Ingredients

-

Ingredient selection

-

At Domino's Pizza Japan, we select only those ingredients that meet our criteria. We assess the supplier, examine official product documentation, inspect the safety measures implemented on the factory floor, and conduct other measures before approving the use of ingredients.

At Domino's Pizza Japan, we select only those ingredients that meet our criteria. We assess the supplier, examine official product documentation, inspect the safety measures implemented on the factory floor, and conduct other measures before approving the use of ingredients.

At Domino's Pizza Japan, we select only those ingredients that meet our criteria. We assess the supplier, examine official product documentation, inspect the safety measures implemented on the factory floor, and conduct other measures before approving the use of ingredients.

-

Quality management

-

We at Domino's Pizza Japan have established a list of safety and quality criteria that all products and ingredients used in our stores must pass. For example, ingredients are tested for a number of bacteria to ensure they are completely safe to use. We also conduct sensory tests related to the taste, color, smell, shape, and other qualities of our products so we can continue improving them. Finally, we conduct periodic health and quality inspections at all factories where our ingredients are produced to make sure customers get the best experience possible.

We at Domino's Pizza Japan have established a list of safety and quality criteria that all products and ingredients used in our stores must pass. For example, ingredients are tested for a number of bacteria to ensure they are completely safe to use. We also conduct sensory tests related to the taste, color, smell, shape, and other qualities of our products so we can continue improving them. Finally, we conduct periodic health and quality inspections at all factories where our ingredients are produced to make sure customers get the best experience possible.

We at Domino's Pizza Japan have established a list of safety and quality criteria that all products and ingredients used in our stores must pass. For example, ingredients are tested for a number of bacteria to ensure they are completely safe to use. We also conduct sensory tests related to the taste, color, smell, shape, and other qualities of our products so we can continue improving them. Finally, we conduct periodic health and quality inspections at all factories where our ingredients are produced to make sure customers get the best experience possible.

-

Distribution chain

-

From our suppliers to our distribution centers

Raw ingredients, non-perishable foods, perishable foods, and frozen foods are transported under proper temperature control to our nine distribution centers, where the products are immediately stored under appropriate temperature conditions. Every day, these products are transported fresh to our over 800 locations around Japan. From our suppliers to our distribution centers

From our suppliers to our distribution centers

Raw ingredients, non-perishable foods, perishable foods, and frozen foods are transported under proper temperature control to our nine distribution centers, where the products are immediately stored under appropriate temperature conditions. Every day, these products are transported fresh to our over 800 locations around Japan.

-

Disclosure of nutritional content, allergens, and calories

-

We strive to disclose information on whether our products contain any of the 27 food allergens that require disclosure under Japanese law. The information is based on our own research into our ingredients. Customers who are allergic to any other food should contact staff for more details.

Note: Although we do our best to disclose all allergens in our products, some allergens that are not used in the product may accidentally end up in the product during the manufacturing or cooking process. Some stores may also use different ingredients to prepare the same product. Customers who are allergic to any food products should consult a doctor and purchase from us at their own risk. We do not generally include allergen information related to dressings, sauces, and other packaged condiments that are provided with the product. We strive to disclose information on whether our products contain any of the 27 food allergens that require disclosure under Japanese law. The information is based on our own research into our ingredients. Customers who are allergic to any other food should contact staff for more details.

We strive to disclose information on whether our products contain any of the 27 food allergens that require disclosure under Japanese law. The information is based on our own research into our ingredients. Customers who are allergic to any other food should contact staff for more details.

Note: Although we do our best to disclose all allergens in our products, some allergens that are not used in the product may accidentally end up in the product during the manufacturing or cooking process. Some stores may also use different ingredients to prepare the same product. Customers who are allergic to any food products should consult a doctor and purchase from us at their own risk. We do not generally include allergen information related to dressings, sauces, and other packaged condiments that are provided with the product.

Store Hygiene

-

Cleaning regimen, cleaning liquid, cleaning equipment, and health checkups

-

At each of our locations, staff strictly monitor the temperatures of the refrigerators and freezers where the ingredients are stored. Before using any ingredient, staff inspect the packaging for tears and other damage and check the ingredient's temperature to ensure that no deterioration in the ingredient's freshness has occurred.

To prevent grime, germs, and other contaminants from spreading around the store, some specialized cleaning equipment is designated only for specific parts of the store. Meanwhile, common pieces of cleaning equipment are color coded to ensure they are used only in specific areas. For example, pink cloths are used only for wiping areas that come in contact with food, while green cloths are used for wiping all other areas (e.g. chairs and doorknobs). Every store is cleaned and disinfected at least every two hours to ensure it remains clean at all times. To prevent germs from spreading from kitchen equipment to the sink area, all items are scrubbed clean with a dishwashing brush that is hung from a hook after every use.

Because different cleaning liquids are used for different purposes, each liquid is stored in a designated container and diluted at a designated ratio before being used. Staff ensure that each liquid is used up or discarded by its expiry date.

We also periodically commission third parties to conduct health inspections, as well as bug and pest control. At each of our locations, staff strictly monitor the temperatures of the refrigerators and freezers where the ingredients are stored. Before using any ingredient, staff inspect the packaging for tears and other damage and check the ingredient's temperature to ensure that no deterioration in the ingredient's freshness has occurred.

At each of our locations, staff strictly monitor the temperatures of the refrigerators and freezers where the ingredients are stored. Before using any ingredient, staff inspect the packaging for tears and other damage and check the ingredient's temperature to ensure that no deterioration in the ingredient's freshness has occurred.

To prevent grime, germs, and other contaminants from spreading around the store, some specialized cleaning equipment is designated only for specific parts of the store. Meanwhile, common pieces of cleaning equipment are color coded to ensure they are used only in specific areas. For example, pink cloths are used only for wiping areas that come in contact with food, while green cloths are used for wiping all other areas (e.g. chairs and doorknobs). Every store is cleaned and disinfected at least every two hours to ensure it remains clean at all times. To prevent germs from spreading from kitchen equipment to the sink area, all items are scrubbed clean with a dishwashing brush that is hung from a hook after every use.

Because different cleaning liquids are used for different purposes, each liquid is stored in a designated container and diluted at a designated ratio before being used. Staff ensure that each liquid is used up or discarded by its expiry date.

We also periodically commission third parties to conduct health inspections, as well as bug and pest control.

-

Cleaning and disinfecting cooking and other equipment

-

Before handling food for cooking, store staff are required to wash their hands for a specified period of time, disinfect them. All areas in the kitchen that come in contact with food are disinfected at least every two hours. These include the assembly line with refrigeration capabilities where the ingredients are stored, the counter where the pizza dough is shaped, and the counter where the pizza is sliced. Pizza cutters and other cooking utensils are also washed and disinfected at least every two hours, with a checklist provided to staff to prevent oversights. All cooking equipment and utensils used during the day are washed and disinfected after the store closes to ensure the highest level of hygiene.

Before handling food for cooking, store staff are required to wash their hands for a specified period of time, disinfect them. All areas in the kitchen that come in contact with food are disinfected at least every two hours. These include the assembly line with refrigeration capabilities where the ingredients are stored, the counter where the pizza dough is shaped, and the counter where the pizza is sliced. Pizza cutters and other cooking utensils are also washed and disinfected at least every two hours, with a checklist provided to staff to prevent oversights. All cooking equipment and utensils used during the day are washed and disinfected after the store closes to ensure the highest level of hygiene.

Before handling food for cooking, store staff are required to wash their hands for a specified period of time, disinfect them. All areas in the kitchen that come in contact with food are disinfected at least every two hours. These include the assembly line with refrigeration capabilities where the ingredients are stored, the counter where the pizza dough is shaped, and the counter where the pizza is sliced. Pizza cutters and other cooking utensils are also washed and disinfected at least every two hours, with a checklist provided to staff to prevent oversights. All cooking equipment and utensils used during the day are washed and disinfected after the store closes to ensure the highest level of hygiene.

-

Health check sheets (covering hand and finger injuries and other details), uniforms, nails, and intestinal examinations

-

All store staff are required to take their temperature before going to work, as well as wash their hands and clean them with alcohol-based disinfectant before starting work. We also periodically conduct intestinal examinations. In this way, we ensure that staff maintain a high level of health and hygiene. Any staff member found to have a fever or an intestinal infection will be asked not to come to work.

All store staff are required to take their temperature before going to work, as well as wash their hands and clean them with alcohol-based disinfectant before starting work. We also periodically conduct intestinal examinations. In this way, we ensure that staff maintain a high level of health and hygiene. Any staff member found to have a fever or an intestinal infection will be asked not to come to work.

All store staff are required to take their temperature before going to work, as well as wash their hands and clean them with alcohol-based disinfectant before starting work. We also periodically conduct intestinal examinations. In this way, we ensure that staff maintain a high level of health and hygiene. Any staff member found to have a fever or an intestinal infection will be asked not to come to work.

-

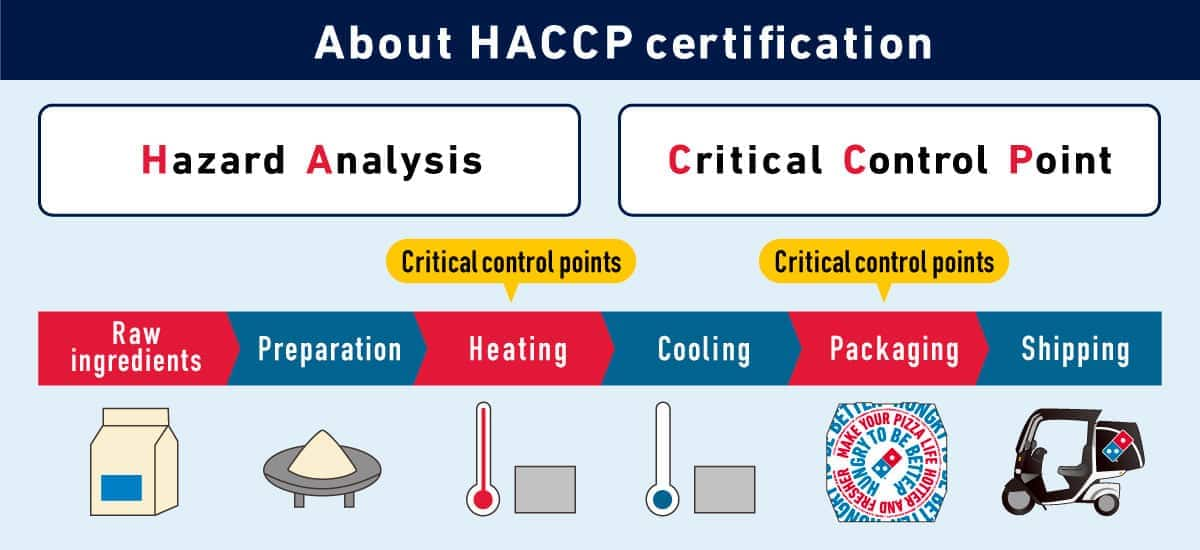

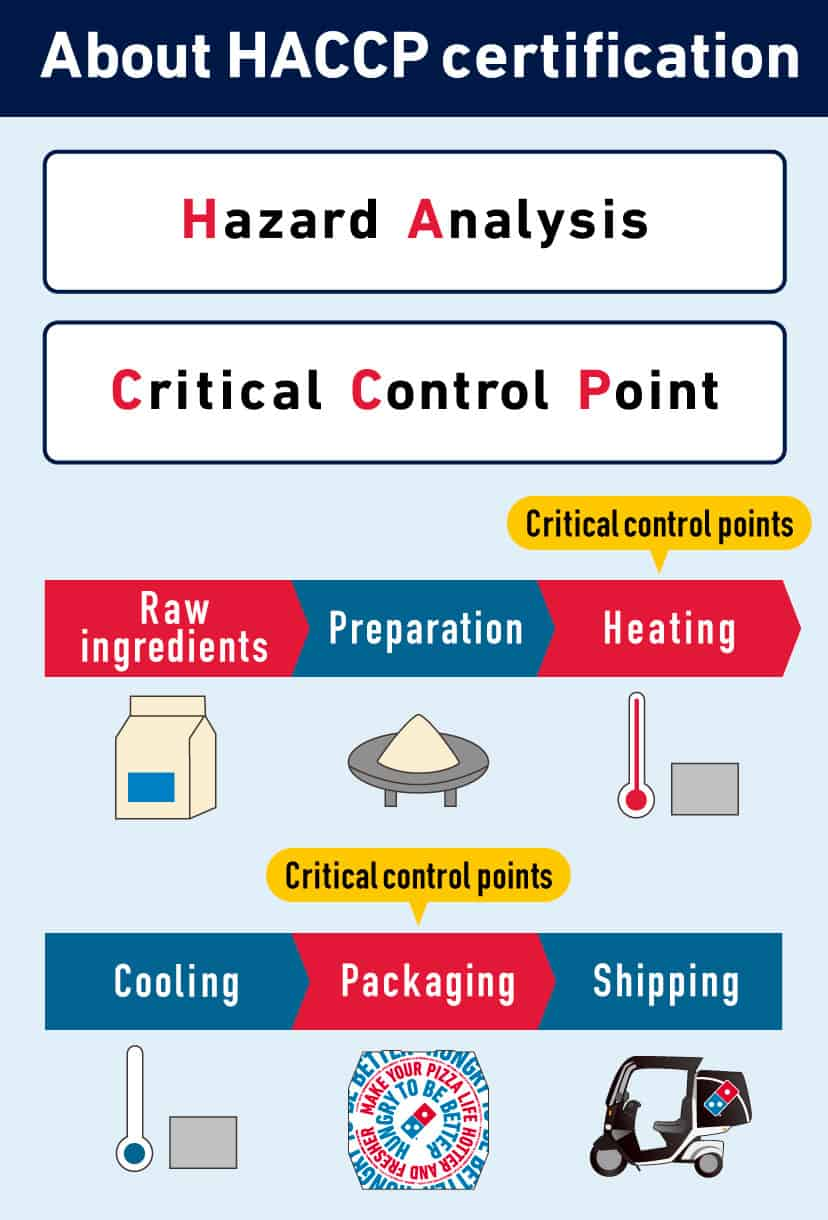

HACCP certification

-

Short for Hazard Analysis and Critical Control Points, HACCP is a type of certification demonstrating a business's dedication to conducting hazard analysis to identify critical control points that require monitoring to prevent situations that could be hazardous to food and health. As a result of revisions to the Japanese Food Sanitation Act approved in June 2020, all businesses that handle food products are now required to get HACCP certification. Businesses were given one year to complete the certification process. In response, we at Domino's Pizza Japan designed our own food safety and hygiene monitoring protocols. Today, over 20,000 staff members in our over 800 franchise and branch locations practice these protocols.

Note: All food safety and hygiene monitoring protocols practiced by Domino's Pizza Japan are incorporated in manuals and educational tools provided to staff. The protocols were formulated based on a guidebook created by the Japan Food Service Association for dining establishments operating multiple locations.

-

Providing food products you can trust

-

As one of the biggest brands in the world, Domino's Pizza has consistently strived to develop a reputation for extraordinary service, high-quality products, and one of the highest levels of food safety and hygiene in the restaurant industry. This is why Domino's Pizza Japan enjoys such a high level of trust among its customers. We at Domino's Pizza Japan promise to continue manufacturing and providing products you can trust, while at the same time making further improvements to our processes and systems so we can guarantee satisfaction to every customer. To achieve this goal, we will strive to do the following:

・Provide complete transparency to our employees, customers, and regulatory authorities in regards to our efforts to adhere to our food safety policies, rules, and standards, and in doing so ensure the safety of our food.

・Provide our customers with products that meet or exceed their expectations, as well as product information that is both accurate and easy to understand.

・Ensure that all employees understand our quality and food safety standards and proactively guide them to work in a way that allows them to meet those standards.

・Develop a corporate culture that encourages continuous improvement so we can achieve the highest level of quality and food safety at every level of our operation, from the farms to our stores.

・Provide proper instruction, support, and guidance at all stores so that all locations are staffed with employees capable of providing the kind of quality and food safety that meet global standards.

Delivery

-

Managing the hygiene of delivery staff

-

Delivery staff are required to wash their hands and disinfect them before starting work, after returning from a delivery, and before and after handing over an order.

Delivery staff are required to wash their hands and disinfect them before starting work, after returning from a delivery, and before and after handing over an order.

Delivery staff are required to wash their hands and disinfect them before starting work, after returning from a delivery, and before and after handing over an order.

-

Drop & Go™

-

If a customer chooses this safe delivery option, staff will first inform the customer of their arrival through the intercom of the customer's home. They will then place an empty pizza box near the customer's front door, on which they will place the order before leaving. This option allows customers who want to or need to limit their contact with other people to order delivery from Domino's without worry.

For more information, click or tap here: If a customer chooses this safe delivery option, staff will first inform the customer of their arrival through the intercom of the customer's home. They will then place an empty pizza box near the customer's front door, on which they will place the order before leaving. This option allows customers who want to or need to limit their contact with other people to order delivery from Domino's without worry.

If a customer chooses this safe delivery option, staff will first inform the customer of their arrival through the intercom of the customer's home. They will then place an empty pizza box near the customer's front door, on which they will place the order before leaving. This option allows customers who want to or need to limit their contact with other people to order delivery from Domino's without worry.

For more information, click or tap here:

-

Smart Drive-Through™

-

If a customer chooses this safe carryout option, they can park by the store and have staff bring out the order to their car. The customer can wait inside their car and limit their contact with other people while picking up their order.

Note: Only available at locations that offer parking (around 300 locations).

For more information, click or tap here: If a customer chooses this safe carryout option, they can park by the store and have staff bring out the order to their car. The customer can wait inside their car and limit their contact with other people while picking up their order.

If a customer chooses this safe carryout option, they can park by the store and have staff bring out the order to their car. The customer can wait inside their car and limit their contact with other people while picking up their order.

Note: Only available at locations that offer parking (around 300 locations).

For more information, click or tap here:

-

GPS DRIVER TRACKER

-

This online service allows customers to track their delivery on a map that displays in real time the delivery route and estimated time of arrival. This service accompanies Pizza Tracker, an online service that allows customers to track their pizza order, from preparation to delivery.

For more information, click or tap here: This online service allows customers to track their delivery on a map that displays in real time the delivery route and estimated time of arrival. This service accompanies Pizza Tracker, an online service that allows customers to track their pizza order, from preparation to delivery.

This online service allows customers to track their delivery on a map that displays in real time the delivery route and estimated time of arrival. This service accompanies Pizza Tracker, an online service that allows customers to track their pizza order, from preparation to delivery.

For more information, click or tap here:

Educating and Awarding Employees

-

Educating part-time and full-time employees

-

Part-time and full-time employees alike receive training through our very own e-learning programs. They are designed to help full-time employees improve their skills, while also providing a solid training regimen to franchise owners and their staff, in the process helping to nurture the entire Domino's Pizza Japan team.

For more information, click or tap here: Part-time and full-time employees alike receive training through our very own e-learning programs. They are designed to help full-time employees improve their skills, while also providing a solid training regimen to franchise owners and their staff, in the process helping to nurture the entire Domino's Pizza Japan team.

Part-time and full-time employees alike receive training through our very own e-learning programs. They are designed to help full-time employees improve their skills, while also providing a solid training regimen to franchise owners and their staff, in the process helping to nurture the entire Domino's Pizza Japan team.

For more information, click or tap here:

-

National Store Training

-

Domino's Pizza Japan organizes three National Store Training events every year, at which all employees learn about the company's compliance and risk management policies. The events are designed to increase employee awareness about customer safety and peace of mind.

Domino's Pizza Japan organizes three National Store Training events every year, at which all employees learn about the company's compliance and risk management policies. The events are designed to increase employee awareness about customer safety and peace of mind.

Domino's Pizza Japan organizes three National Store Training events every year, at which all employees learn about the company's compliance and risk management policies. The events are designed to increase employee awareness about customer safety and peace of mind.

Food Safety Management

-

Organizational chart related to food safety

-